Quality control process

Main objective of Roda SA is to offer quality products. Based on this value, at all stages of production quality control is carried out for all received raw materials and products.

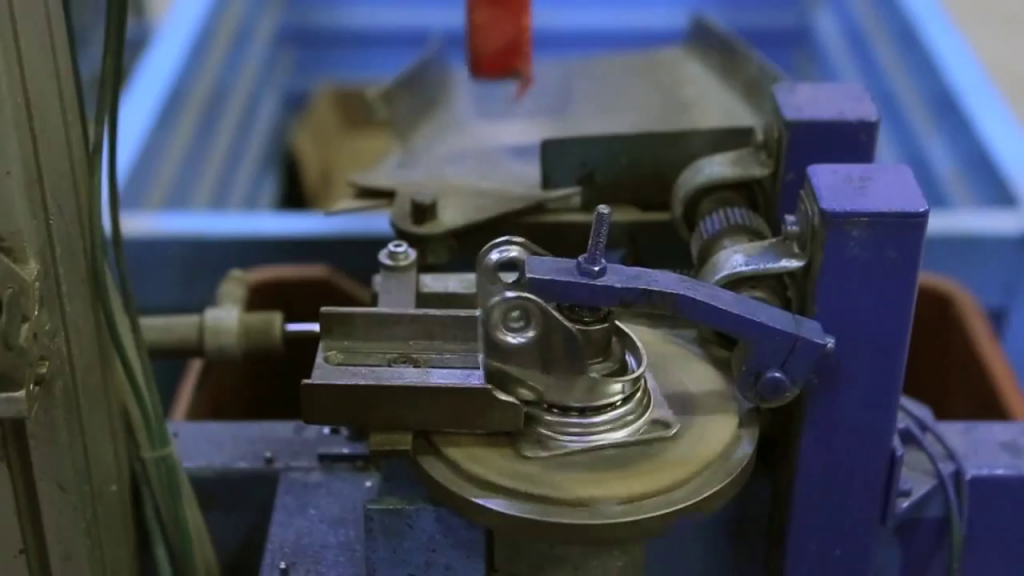

At each stage, from the pressing of the metal products, to the final assembly of the wheel with the base, a sample check is carried out.

More specifically, after the production of metal products, their critical dimensions are measured with special gauges, so that they are within the tolerances defined from the beginning. After specific productions, the molds are taken to the machine shop for the required maintenance to ensure seamless future production of the parts with the same characteristics.

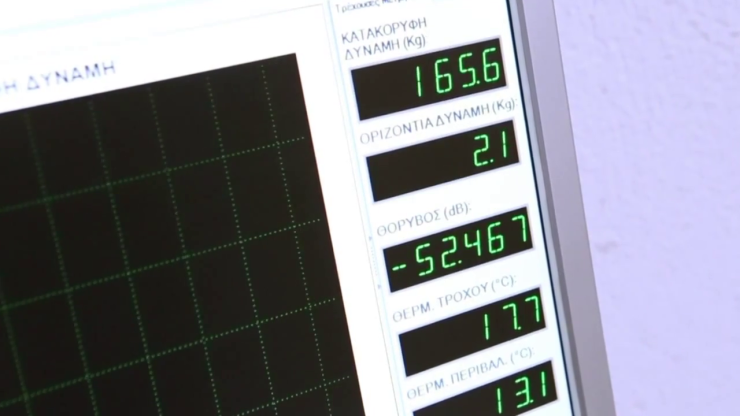

There is also the possibility to measure the strength of the wheel under a certain load (up to 1.5 TN), the rolling resistance of the wheel, the noise as well as the temperature that develops.

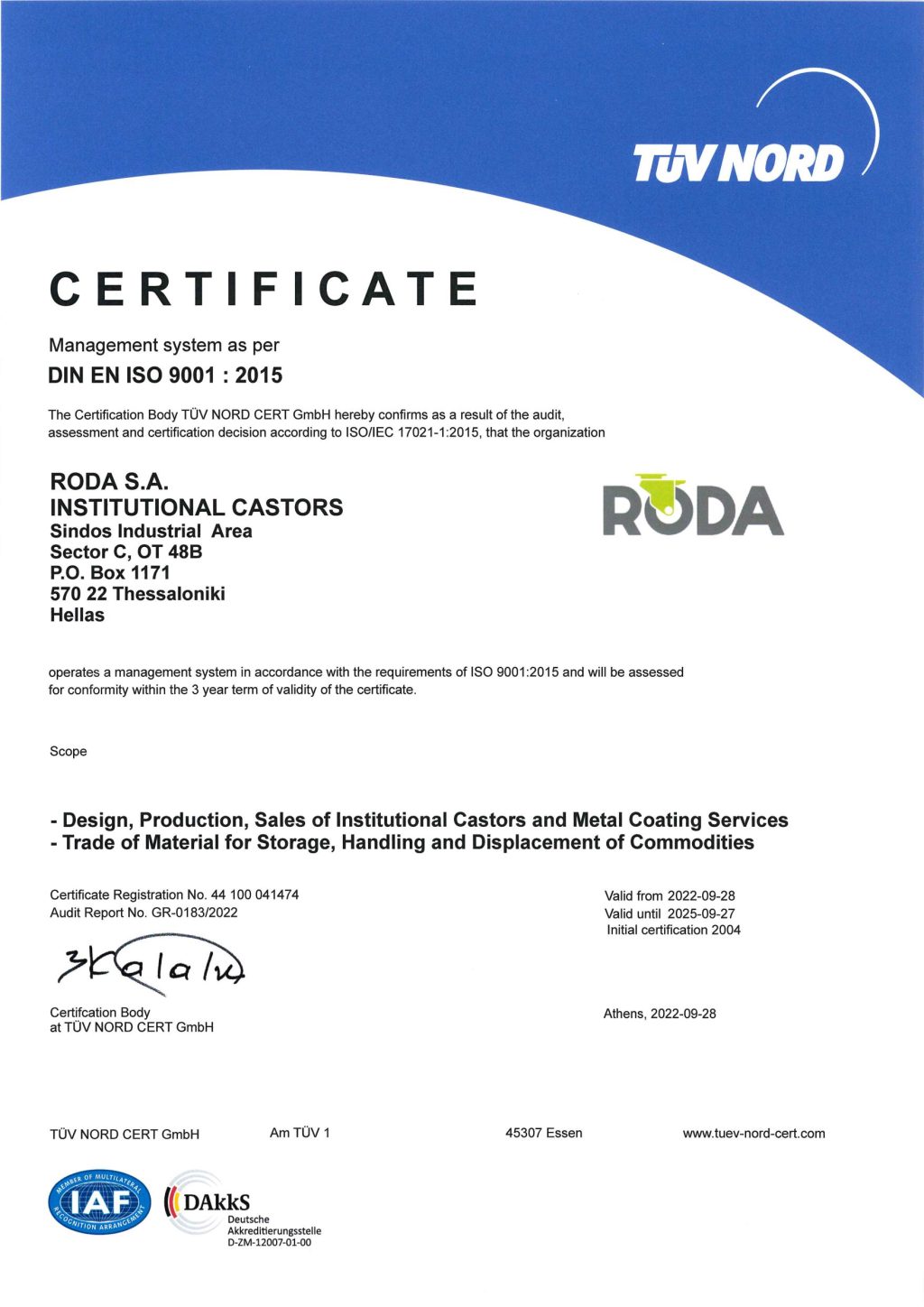

Quality Certificate

Our company has a quality management system certificate from TUV NORD CERT GmbH., according to DIN EN ISO 9001:2015. The fields of application of the quality system concern the Design, Production and Sales of Institutorial Castors and Metal Coating Service, as well as the Trade of Material for Storage, Handling and Diplacement of Commodities.

is a Greek manufacturing company, producing the whole range of castors and wheels for institutional applications.

is a Greek manufacturing company, producing the whole range of castors and wheels for institutional applications.